Although RO (reverse osmosis) membranes are capable of maintaining high water quality over extended periods of time they eventually will begin to deteriorate. Normally, the conductivity of the permeate (output or “clean” water) will increase as the membranes age. By comparing the difference in total dissolved solids (TDS) readings between the Tap water (inlet water presented to the membrane for treatment) conductivity and the permeate water conductivity, the percentage of rejection of the RO membrane may be calculated and the resultant number may then be used to determine the condition of the membrane and thus the operator will know when the membrane needs to be replaced. Membrane failure will be indicated by a reduction of the percentage of rejection which will be determined by calculating the differential between the input and output numbers.

In order to accurately determine the condition of the RO Membrane, a decent quality conductivity tester (TDS meter) capable of reading the tap water conductivity and the permeate water conductivity should be used. With the assistance of the TDS meter you will be able to easily determine the RO membrane’s condition.

Before performing the diagnostic test on an RO membrane, make sure that the RO system has been “ON” and producing pure water for a minimum of 10 minutes. Also check the brine (waste) line (usually yellow) to make sure that water is flowing and that the flow ratio between the permeate water and the brine water is at a ratio that is > 4 to 1. NOTE: The pressure gauge should indicate a pressure reading of > 40 PSI during this 15-20 minute test period. Rejection rates less than 95% may indicate that the membrane should be replaced.

As a general rule; the RO membrane would be considered in good condition when the rejection rate is = to or > 95%.

Why is rejection so important?

The RO membrane is the workhorse of the water purification system. It uses a thin film membrane technology to reject impurities. RO membranes are especially good at rejecting large atoms and molecules and those species that exhibit relatively strong electron charge. It is less effective in rejecting small atoms and molecules (smaller than water) and those with relatively weak electron charge. RO membranes will allow all dissolved gases (such as ammonia and carbon dioxide) to pass through. The % rejection rating for a membrane is an indication of how much of these impurities will pass through the membrane and on to the DI cartridge. A membrane that has a 98% rejection rating will pass only half as many of these impurities as one with a rating of 96%. The direct result of using a 98% rejection membrane as opposed to a 96% membrane is that you will double your DI cartridge lifetime. It is important to note that all membrane manufacturers adhere to a lower % rejection limit for small membranes (2″ x 10″) of 96% at 60 psi and that the only way to ensure that you are using a higher % rejection membrane is to purchase it from a source which screens for higher % rejection membranes. Spectrapure membranes are treated with a proprietary process to enhance % rejection and production characteristics. We have been testing our RO membranes for over 20 years to the industry standard of 60psi. There is a significant amount of data for us to draw upon when we share performance characteristics with our customers, help them troubleshoot production problems, or back up our ratings claims, for that matter.

How to Know It’s Time to Replace Your Reverse Osmosis (RO) Membrane

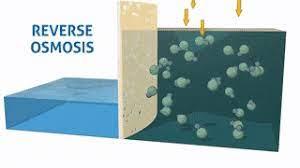

Reverse osmosis, or RO, is one of the finest technologies to purify water containing high total dissolved solids (TDS) levels of more than 500 ppm. Reverse osmosis plant exporters explain the technology as a separation technology where dissolved and invisible impurities in water are separated with the help of a semi-permeable membrane or RO membrane that works under high pressure.

Constituents of impurities and dissolved solids are magnesium salts, calcium, iron, nitrates, lead, fluorides, arsenic, etc. These constituents are usually found in groundwater. In urban areas and cities, groundwater is distributed through municipal pipelines and sometimes water tankers are also employed to meet the demand of water supply. Minerals like calcium and iron are good for human body, but other impurities such as lead will harm in the long run.

The RO membrane is a critical part of the reverse osmosis system. It is a thin film that is made up of microscopic pores. In normal operation, the membrane used in RO elements can become contaminated by biological matter, mineral buildup, insoluble organic contaminants, and colloidal particles.

Apart from contamination, the membrane can get clogged to the extent that they can become ineffective in removing the dissolved salts effectively, cause a drop in the output of filtered water, or both. This is why most RO purifier models designed for domestic use are fitted a with UV purification feature to eliminate the chances of contamination.

It is important that water should first flow via a pre-filter in order to protect the delicate RO membrane, extend its life, and to prevent frequent fouling. This pre-filter cartridge will filter the water and make it free from the dirt, sand, silt, and other suspended sediments. You need to change this filter every six to nine months or as per the water-quality supply you are getting. If you take this filter lightly or ignore it too long, it can foul or get clogged. This will affect the life of your RO membrane.

RO water purifiers are an expensive but superb way to remove toxins and contaminants from water.

How Do You Know If RO Membrane Is Bad?